Arc protractor

Instructions

Our arc protractor generator is the definitive tool for making printable custom protractors, specifically for your turntable.

The great advantage of an arc protractor is that it separates the overhang adjustment from the offset angle. With 2-point protractors, both are set at the same time, which can be confusing and time consuming. The arc protractor makes turntable setup a lot easier.

The arc gives you visual confirmation of the correct overhang. With sightline protractors, there can be some uncertainty whether it's pointed precisely at the tonearm pivot or not. This is not the case here. There is no doubt with an arc protractor.

Please note that arc protractors are not universal. They need to be generated for your turntable’s specific pivot-to-spindle distance.

Using the arc protractor generator

Labelling your template

The turntable input field sets a name for the template, allowing you to identify for which model the protractor was generated.

Finding out the pivot-to-spindle distance

Pivot-to-spindle distance is the only variable you actually need to know. It varies from turntable to turntable. Most record player manuals will give you a specification for effective length and overhang. Simply subtract overhang from effective length to get the pivot-to-spindle distance. Please note that actually measuring the distance may give you a more accurate result.

Choosing the right geometry for your records

There are several standards for the radii of the inmost and outmost modulated (i.e. recorded) grooves of an LP record. Simply choose the standard you prefer:

- DIN (IEC 98) is a German standard and will use the smallest inner groove radius (57.5 mm),

- IEC/RIAA (IEC98-1958, RIAA-1963), an international standard, the largest (60.325 mm). Both use the same outer groove radius (146.05 mm).

- JIS (S8502-1973) is a Japanese standard and uses a slightly larger inner groove radius than DIN (57.6 mm) and the largest outer groove radius of the three (146.5 mm).

These are the most commonly used dimensions. They were chosen to keep the generator compatible and comparable with other protractors and calculators. DIN and IEC both have been specifying a larger outer groove radius of 146.3 mm since 1964, but this is not as commonly used and will not make much of a difference. But you may still use them if you want to. The custom option allows you to enter any groove specifications.

But which of these groove dimension standards should you choose? It depends on your records! Tracking distortion will be minimized in the specified modulated area. This is particularly critical for the inner grooves, as distortion increases significantly beyond the inner null point. So measure a couple of records with a narrow dead wax and choose wisely. It is usually best to optimize for the longest records in your collection. For easier measuring, you may print out our record ruler.

When optimizing for 10″ or 7″ records or for modern records with a very wide dead wax area, other groove dimensions can be entered by choosing custom. 7″ records can have an inner groove as small as 53 mm (JIS-1966). When optimizing for 7″ as well as 12″ records, you may want to consider this.

Choosing the right alignment method

Based on the groove radii, the null points are calculated according to the alignment method. Which strategy you should choose again depends on your personal preferences. They all try to optimize tracking distortion, but in different ways:

- Baerwald (also known as Löfgren A) is generally considered to be the best compromise that minimizes distortion across the record and keeps the distortion at the inner and outer grooves low.

- Löfgren B will give you the lowest RMS distortion, but increased error at the inner and outer grooves.

- Stevenson optimizes for the least inner groove distortion at the expense of increased average distortion.

- AP™ is our proprietary alignment with reduced tracking distortion at the inner grooves (where tracing distortion is a problem) and increased tracking distortion at the outer grooves (where tracing distortion is low).

- custom allows you to set your own null points or calculate null points for a known geometry. This is particularly useful if you need to match the manufacturer alignment of your turntable or if you would like to experiment. Note that when choosing this option, the groove specification setting will make no difference.

Please note that each combination of null points and alignment method will result in a different overhang and offset angle. This is normal. The manufacturer recommended overhang and offset angle must be ignored when using a protractor.

Printing and saving your custom protractor

Make your choices, calculate the specifications of your protractor or generate one right away by clicking on the buttons and print out the arc protractor template at 100 % scale (to be set in the printing dialogue). Setting print quality to “high” will help getting a good and accurate result.

When printed, the outer square should measure exactly 190 × 180 mm. If it does not, it will be necessary to adjust the printer correction factors accordingly.

Safari and iOS users please use the PDF download option to avoid scaling issues.

You may also download the SVG and save your custom phono cartridge alignment protractor to your hard drive. Another way to save your alignment template for future use is to simply set a bookmark in your browser. All the parameters of your arc protractor are stored in its URL. This also allows to simply share the link with others.

To protect your stylus, printing the template onto glossy photo paper is recommended. You may also stick pieces of clear parcel tape to all points to which you lower your stylus, or laminate the alignment protractor.

Cutting out the spindle hole

Now cut or punch out the spindle hole as accurately as you can. Some prefer to perforate the outline of the spindle hole with a needle and then punch out the center, others use a sharp knife and a straight edge or metal ruler. A great tool for this job is a 9/32″ or 7 mm hole punch. Cut off the excess paper along the dotted line and place the protractor on your turntable.

ADVERTISEMENT*

Aligning the cartridge

Deactivating the anti-skate mechanism

Set anti-skating to zero to ensure there is no force that pulls the cartridge outward during alignment.

Setting the overhang on the arc

First, the overhang is set by adjusting the cartridge position so that the stylus tip traces the arc on the template perfectly: Set the stylus on the arc line near the edge of the record. Then lift it and set it down close to the spindle. If it comes down right on the arc, the overhang is set correctly. If it is short of the arc, overhang needs to be increased by moving the cartridge forward in the headshell. If it is beyond the arc, decrease overhang by moving the cartridge backwards.

If the slots in your headshell are too short for setting the correct overhang, you will have to choose a different alignment strategy with a shorter or longer overhang.

If it turns out to be impossible for the stylus to trace the arc, your measurement of the pivot to spindle distance or the print scale may be off.

Once the stylus follows the arc, the overhang is set and the cartridge alignment protractor is perfectly placed on your turntable. It must not be moved for the rest of the procedure. At this point, it is best to move the cartridge back a tiny bit in the headshell. This is because a stylus placed on a spinning record will be pulled forward a little more than a stylus that is placed on a stationary record or protractor. By moving it back, you ensure that the stylus will be right on the arc when a record is spinning.

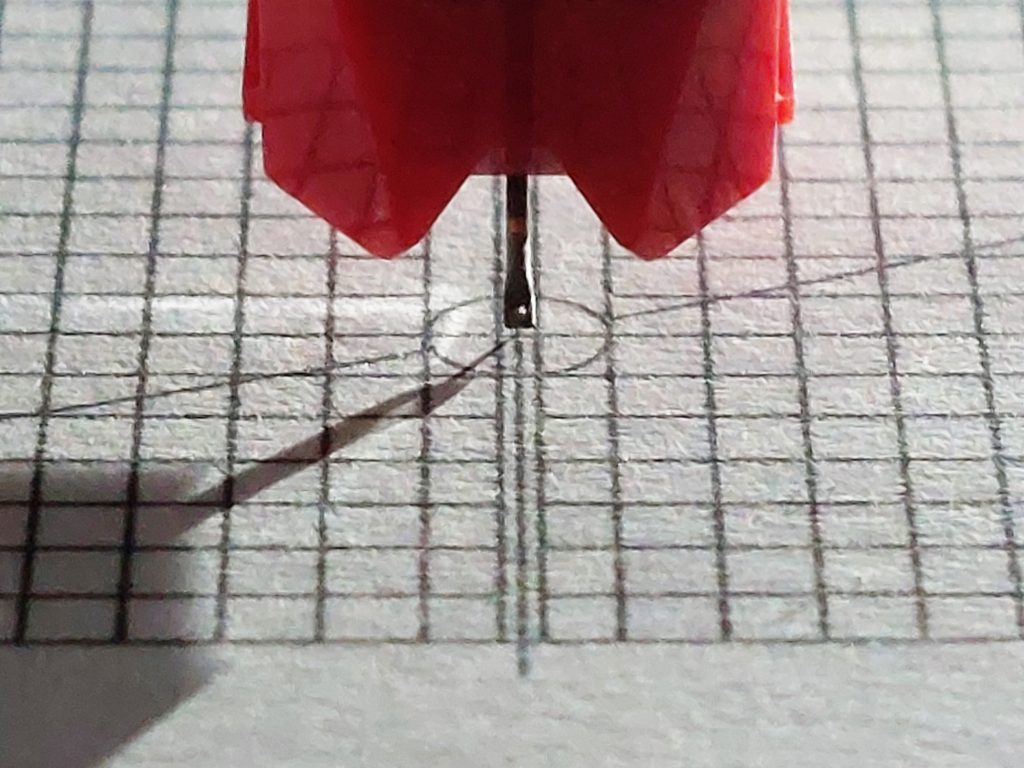

Setting the offset angle

Set the offset angle by aligning the cartridge body or cantilever to either grid. The stylus tip needs be lowered exactly to the center of the grid for a good result.

When aligning a cartridge body with a flat front, greater accuracy can be achieved by taping a pencil lead to it.

To be able to align the cantilever, it is necessary to decrease the tracking force to under 0.5 g. Make sure to look at the cartridge in a straight line to avoid parallax error. This is easiest to see from a low angle.

A magnifying glass or phone camera can be of great help here. Set up enough lights to eliminate any shadows under the cartridge. Activate the grid in your camera app and make sure the horizontal lines of the protractor grid are parallel with it. The vertical line to which the cantilever is aligned should be parallel with the vertical grid lines.

This is what you want to see:

Please note that the cantilever may deflect when a highly compliant cartridge is lowered onto the protractor, especially if the surface is rough and the stylus cannot move. Lowering the vertical tracking force should pretty much elimimnate this issue. If it does not, it is best to keep the stylus just above the protractor and to not lower it down or to align the cartridge body instead of the cantilever.

Checking alignment on the second grid

Once you are happy with the alignment, you may double check on the other grid. Make sure that the overhang is still set correctly.

Setting the tracking force and anti-skate

Do not forget to set the vertical tracking force and anti-skate back to their correct values when you are done.